HMT MACHINE TOOLS LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HMT MACHINE TOOLS LTD

Vertical Machining Centers

Salient Features :

» Machine structure designed for optimum performance from static, dynamic and thermal aspects.

» 12-Tools armless tool changer

» Z-Axis on the spindle and X, Y axes on the table

» Dynamically balanced cartridge type spindle unit.

» Direct coupled ballscrews with feed motors

» Absolute encoders for all axes

» Space saving and single lift type design.

» Rigid tapping

» High pressure coolant system

» TPM Friendly machine

» TPM Friendly machine

» Head counter balance

Die And Mould Machining Centers

Salient Features :

» High speed, high power integral spindle

» Cartridge type spindle arrangement mounted on the ram for easy dismantling during servicing

» Automatic spindle temperature cooler

» LM guides for X & Y axes

» Ram structure for Z-axis with enveloping guideway design with large contact area to ensure good cutting performance throughout the stroke

» Optional rotary table with tilting axis for a full-fledged five-axes machining

» Total clamping through disc springs and declamping through pneumatic

» Cam operated armless 24 tools ATC

» Minimal hydraulics

» Counter balancer to ensure zero drop during power failures

Cnc Tool Room Milling Machine

Salient Features :

» Versatile Tool Room Milling Machine with capability for milling,drilling, tapping & boring at any angle.

» The machine is equipped with 3-axes AC servos and variable frequency drive for spindle with 3-axes AC servos and variable frequency drive for spindle with state-of-the art Siemens 802D CNC system. All axes fitted with LM bearings.

» Equipped with 40-3000 rpm 1.5 kW spindle with variable frequency controlled ball bearings for spindle.

» Can ideally be used for tool room applications and in automobile and auto ancillaries, small industry and educational & training centres.

Drilling And Tapping Center

Salient Features :

» Compact 3-axes CNC Drilling & Tapping Machining Center.

» Main spindle built with integral motor with oil cooling for high speed applications.

» Preloaded linear recirculating guideway system for X, Y, and Z axes for high speed positioning.

» AC servomotors for feed drive.

» Spindle orientation and power draw bolts.

» Rigid tapping - 1 pitch per 1 revolution.

» Turn table with pallet.

» Efficient coolant and chip disposal.

» Automatic cyclic lubrication system.

» Coolant through spindle (optional)

» Guideway protection through telescopic and bellow covers.

» Cam operated fast auto tool change system. Armless ATC on DT 40. Linear type ATC on BLITZ 30

» Useful for auto & auto ancillaries, electrical & electronics industries, instrumentation, defence, aerospace & general engineering industry for machining on steel, cast iron, aluminium

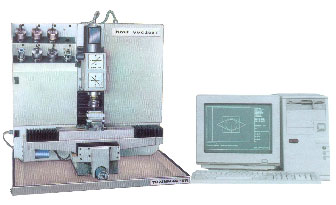

Training Machining Center

Salient Features :

» An economical and user friendly PC based system to meet Training requirements of all Training Centres, Technical and Educational Institutions in CNC machine tools operation & programming.

» Provides a comprehensive range of CNC functions for both Vertical and Horizontal modes of operation, with a CRT monitor and many more advanced features.

» PC based CNC system

» Compact table top model, most ideal for training institutes.

» Stepless DC drive with RPM and load indication for spindle.

» Hardened and ground spindle runs in Precision antifriction bearings.

» Economical CNC system best suited to educational institutions.

» Recirculating Ball screw and Nut arrangement for all axis

» Machine lamp

Milling Cnc

Salient Features :

» Rectangular box construction made of weldment with sufficient ribbing for rigidity.

» Cross beam generously ribbed to take up extreme cutting loads.

» AC Spindle motor for main drive.

» LM Guides.

» Compound slide comprising of Y axis and Z axis integral to the milling head is driven by AC servomotors coupled to the ballscrews through timer belt and pulleys.

» Two pallet bases.

» All bearings lubricated for life.

» Efficient chip disposal system.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.